The customer’s product used three different custom made 12-position rotary switches originally, supplied by WASP Switching Products. Their switch family uses stacked switch wafers to provide a large and bespoke number of poles. Originally manufactured in the tens of thousands, a couple of dozen three switch sets were needed for servicing existing in service units. The switches were never a low cost part anyway, even in the high initial volumes, but the piece part price was almost prohibitively expensive for the low volumes required. Worse still, this requirement came at a time when one of the knock-on effects of Covid-19 was extended lead times for a wide variety of components. With the customer needing to deliver his product in a few weeks, and the switch lead times looking to push this to nearer a year, an alternative solution needed to be found.

So component availability became the key driver in the circuit design. The chosen solution was to use an off-the-shelf 12-way one pole switch as the source of control signals to a programmable logic device, which would then generate the desired multi-pole output, via external components where necessary. The tiny PCB area available (about one square inch) put very severe constraints on the range of choices for a programmable logic device, as only the smallest of devices could be made to fit. Ideally it would have been from a family which was live at power-up, but no such device seemed to exist, so a work around was needed. Even though any programmable logic device was likely to be correctly configured by the time the main system processors came out of reset, a few additional discrete components had to be added. These would ensure that during the uninitialised state of the programmable device the outputs of the electronic switch would forced the system into a safe state, regardless of the actual setting already present on the core 12-way one pole switch, at the start of a particular power up cycle.

The redesigned switches also needed a new mechanical adapter on the switch shaft to allow it to pass through the unit front panel and couple to the existing control knob to make it truly form, fit, and function compatible with the WASP switch. Not only did this redesign allow the customer to ship product to the end user in with an acceptable timescale, but even allowing for the non-recurring engineering cost, the total cost of the small batch of switches was less than that of the original WASP parts of a similar sized order. So a win-win situation for future orders, as any subsequent batches manufactured will have a very much lower per unit cost than the original parts.

Oh. and the chosen programmable logic device? A Lattice Semiconductor MachXO2 in a 32-pin QFN package.

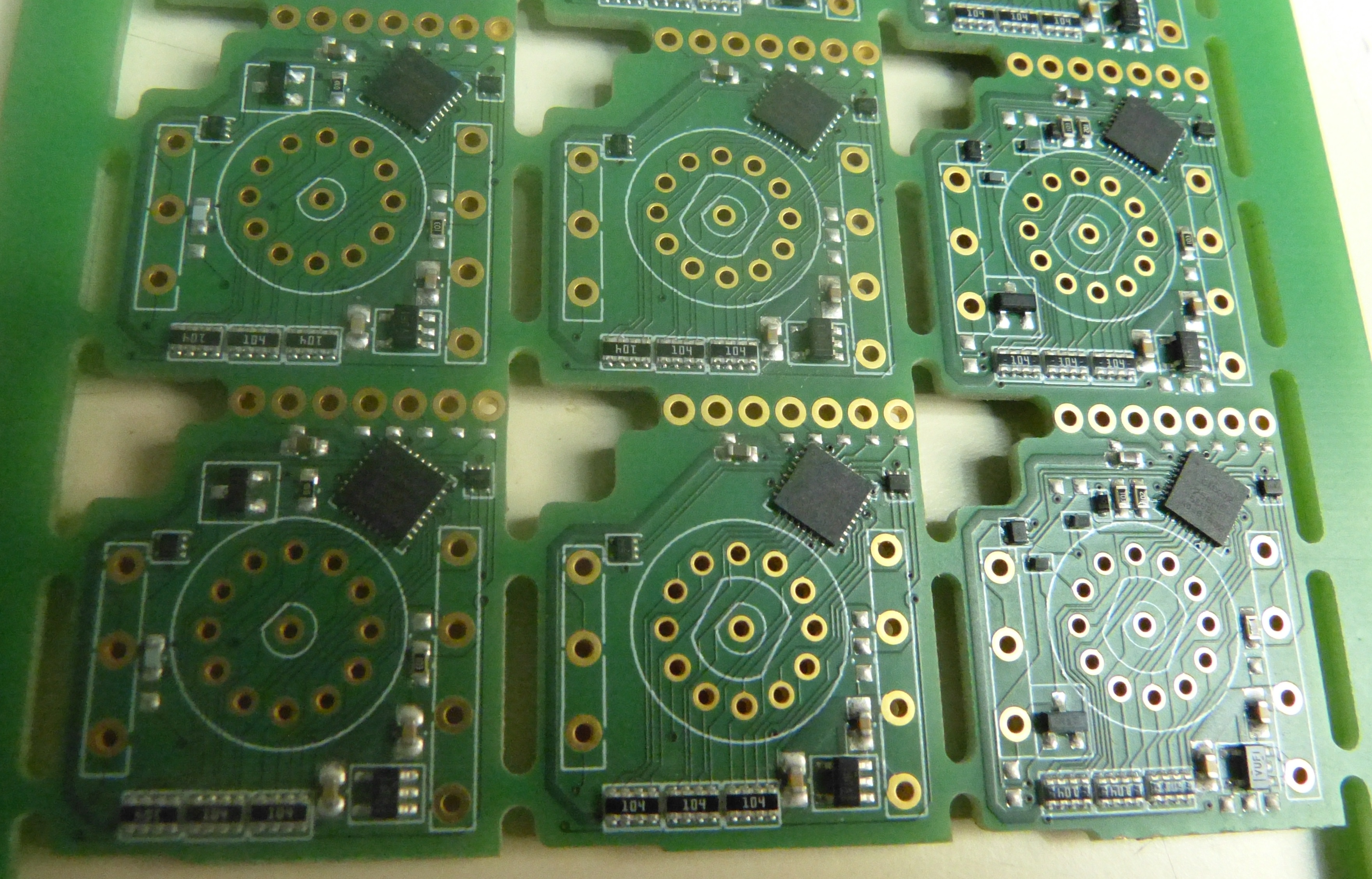

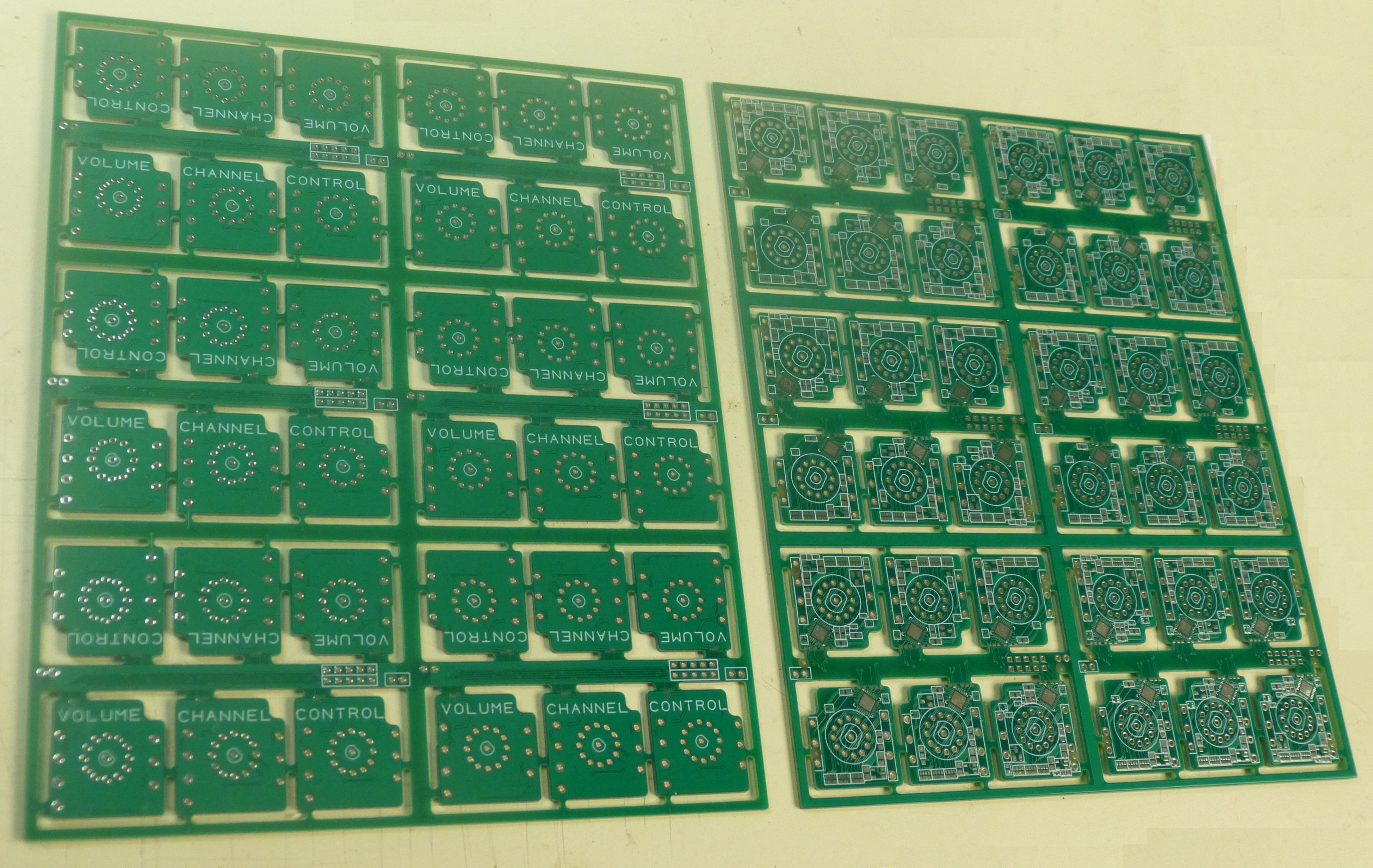

You can click on the images below to enlarge them. They show an both sides of an unpopulated PCB substrate and a set of boards populated with their surface mount components.